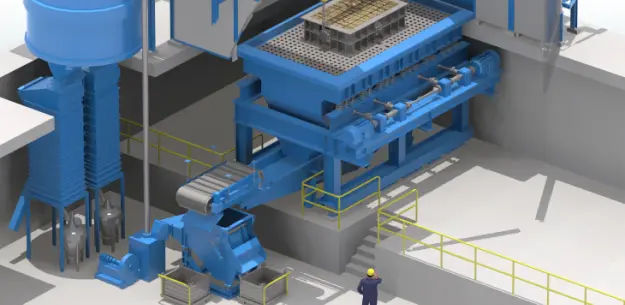

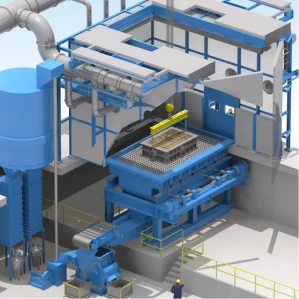

Country’s largest semi-automated heavy fast-loop moulding line

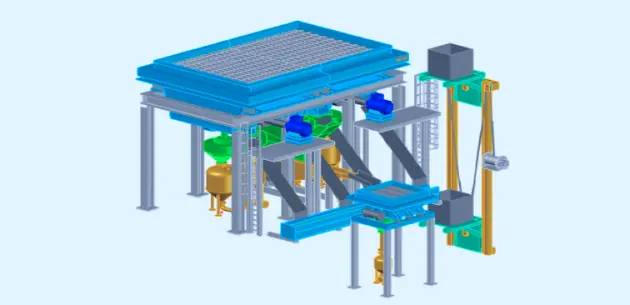

Continuous sand mixers with automated flow control system

Well established CNC Pattern Supply Chain

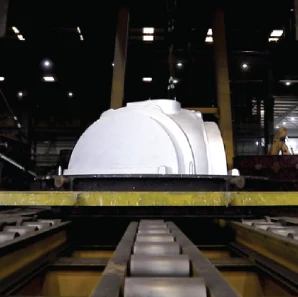

Induction furnaces having capacity of 33 MT single piece

Mechanical Sand Reclamation: Having 1200MT/ Day

Shakeouts: 6 X 6 Mtr., Grid size Max. Size -80MT load bearing Capacity

Thermal reclamation plant : Having 3MT / Hr capacity

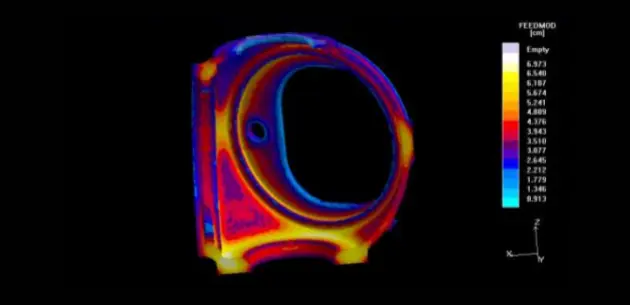

Magma flow analysis and thermal simulation software

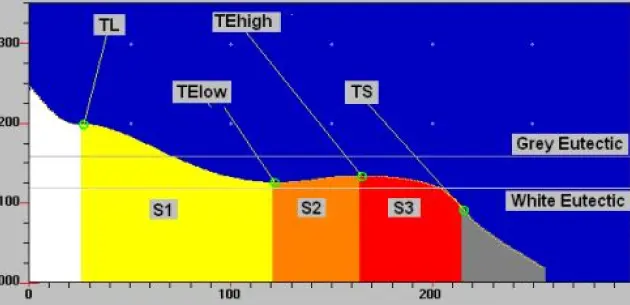

ATAS thermal analysis system

Complete solution for ready-to-assemble components from new product design, development, testing, and pattern supply chain, to stringently quality-tested final delivery

© Copyright 2023 Synergy Green Industries Ltd.